In the spirit of giving away ideas that might make a difference, I’ve written this wind turbines post to bang on about an idea I had years ago.

I’ve searched the internet over the last few days and I haven’t found anyone else who’s had the same idea. Either that means it’s a terrible concept that won’t work or – and I hope this is the case – it is genuinely new and workable. On the other hand, it may well end up as another entry on the Questionable Concepts page of Wind-Works.org but if I keep the idea to myself, I’ll never know.

Wind Turbines and Turbulence

The problem with wind turbines, as far as I understand, is that they are less efficient in turbulent conditions. For example, in an urban area a wind turbine for home will be less effective than an offshore wind turbine. The same goes for wind turbines on the roofs of city buildings.

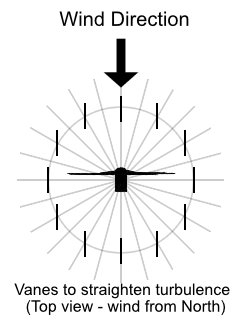

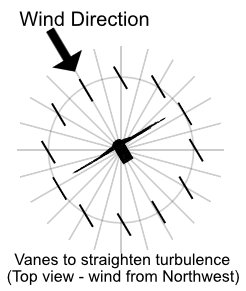

I propose that surrounding a horizontal axis wind turbine (HAWT) with vertical vanes that reduce the turbulence will help increase the turbine’s power output. The vanes would have to swivel about their vertical axes to keep their leading edges facing into the wind, i.e. each vane would swivel about its vertical axis at the same time as the turbine swivels to face into the wind.

In the next diagram the wind has moved around to the northwest. The vanes all swivel automatically to align with the new wind direction.

If just straightening out the wind is all that’s required then the vertical vanes could be be mounted on a simple bearing that merely allows the vanes to keep themselves aligned with the wind (maybe with a damper to prevent them oscillating). For a self-aligning vane it would probably help if the bearing was mounted towards the front of the vane, not halfway as in my diagrams.

However, I wonder if it’s possible to make the vanes do more than smooth out turbulence?

Increase the Flow

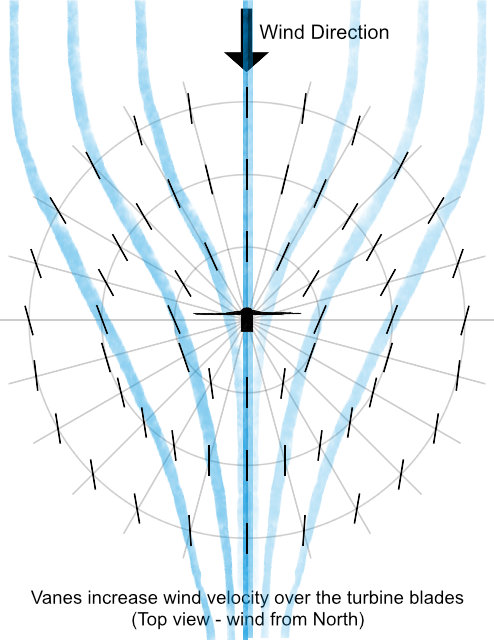

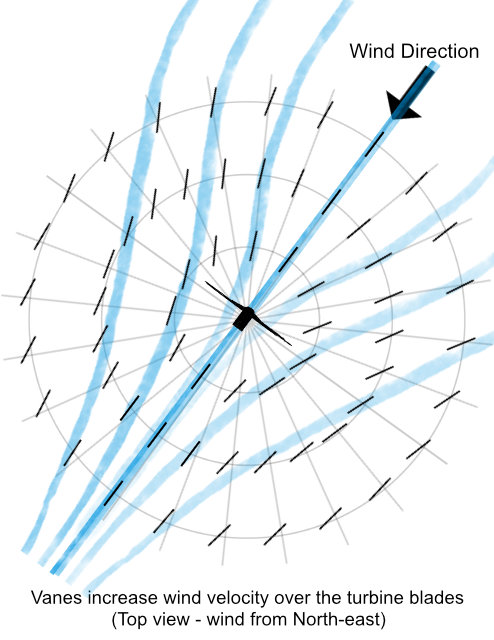

What I mean is: could the angles of the vertical vanes be angled to “funnel” air to the turbine? This would exploit Bernoulli’s principle and cause the narrowed stream of air to flow faster, increasing its kinetic energy, and thus cause the turbine to spin at a higher rate.

This means that each vane would have to be hooked up to a servomotor that is controlled by a central system. The system would have to adjust the angle of each vane in order to produce the desired flow. This alone might make the entire system too expensive to be practical. But, hey, nothing ventured, nothing gained.

Before I carry on, I’d like to point out that I’m not an engineer. My knowledge of aerodynamics is rather on the empirical side and comes from building and flying model planes. If my big idea turns out to be as useful as nuclear-bomb-proof paint then please let me know in the comments.

When I first dreamt this up, I thought I’d build a scale model to test the idea. Years went by and I never got around to it so, hopefully, someone else will pick up the idea and run with it.

Bearing in mind I haven’t done any testing, I reckon that two or three rings of vanes would do the trick.

Below are a couple of diagrams showing plan views of what I mean. They aren’t to scale and the angles of the vanes have been eyeballed, not calculated, but I hope they give an indication.

The first diagram shows the wind blowing from the north. Each circle of vanes is adjusted by controlling software to funnel the air towards the turbine blades.

A second row of turbines at the rear of the outside circle of vanes could exploit the fastest region of moving air, though this might make the whole setup too complicated.

In the next diagram, the wind direction has shifted to the north-east. The vanes are automatically adjusted by a central system to accommodate the new wind direction.

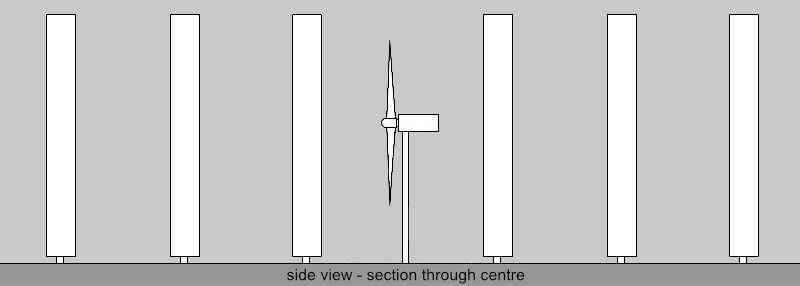

Here’s a side view showing a cross-section through the centre of the arrangement. I reckon the vertical vanes need to be slightly taller than the height of the turbine to avoid the tip vortices from the vanes interfering with the turbine blades.

In strong winds, the vanes could all be straightened (i.e. all are set at the same angle as the wind direction) if required to reduce stress on the turbine blades.

Let me know in the comments if you think this would work. If it is workable and assuming someone else hasn’t already patented the idea, anyone is welcome to use the above, develop it further and even take it to market. I’m not asking for payment, all I ask for is acknowledgement – including a link to my website.

Leave a Reply